CLIENT SELLS PRODUCT TO MAJOR RETAILERS.

But there’s one minor problem.

THE CLIENT CHALLENGE

The good news for our client: Wal-Mart, Target, Bed Bath and Beyond and a handful of smaller retailers picked up their product. The not-so-good news? Our client realized that they lacked optimal facility space and manpower for this significant increase in volume. And that’s not all. They also needed UPC labeling and Electronic Data Interchange (EDI) capabilities, plus visibility and tracking of the various components needed to assemble and complete the finished product. Plus, over 3,700 displays needed to be assembled, filled, packed and labeled to meet the retailer routing guide requirements and Advanced Shipping Notices (ASNs) sent. Oh yeah, and there was a Black Friday due date. It was enough to make any 3PL nervous. But King Solutions isn’t just any 3PL.

THE KING SOLUTION

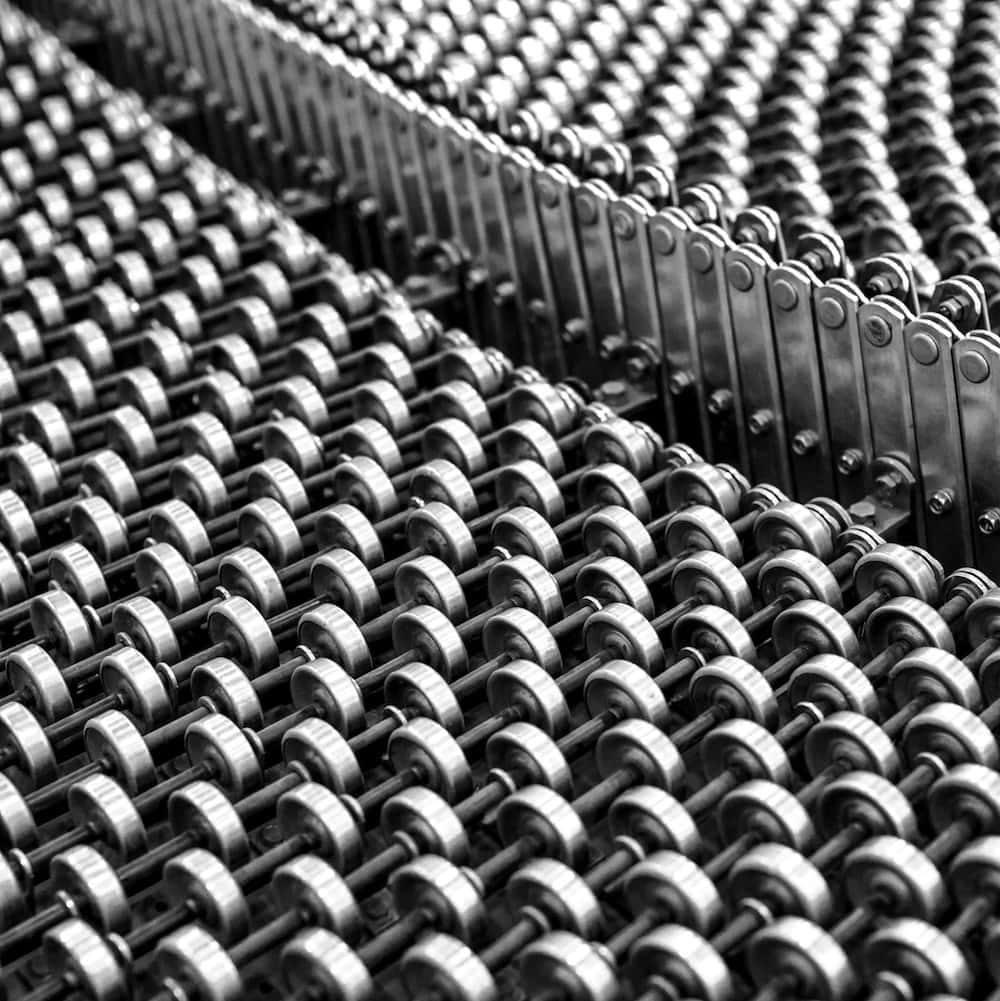

The first step? In a word, outsourcing. Our client’s print partner shipped components to King’s facility, where we could receive them into our inventory management system for total visibility of all components received. This freed up our client’s office, dock and manpower, so they could run the rest of their business. Once all components were received, King assembled, labeled and inventoried the various POP display configurations. Now all products were ready for orders to be received to fulfill and ship. Next, King got EDI and ASNs, ASAP. EDI is a necessary capability needed in order to ship product to a retailer, and all of the retailers needed ASNs in this project. The third-party program our customer was using wasn’t working sufficiently, so we rolled up our sleeves and were able to perform significant amounts of data entry in order to meet these retailer requirements. This allowed for faster invoicing, which meant faster payment. You could say our client liked that quite a bit.

THE END RESULT

Outsourcing to King allowed an up-and-coming company to successfully meet the requirements of major retailers. King provided instant relief from space and manpower constraints, and our knowledgeable fulfillment department met the challenge of assembling the volume and delivering to retailers by their PO due dates. All of this avoided retailer charge-backs and allowed for more sales and new programs. The flexibility and capabilities King has provided have given our client the comfort to commit to these same volumes next year. But we’re not stopping there. King has also become involved in other areas of our client’s distribution activity, strengthening and developing our partnership along the way.

“King was able to assemble, pick & pack, label and ship our product to nationwide retailers. Their ability to take on large fulfillment orders in a short period of time while following each retailer’s strict guidelines put our worries at ease. We look forward to a long partnership of fulfillment, shipping, warehouse solutions and much more.” Angie Hanzal, Operations Manager–30 Watt

Joel Rice

Joel Rice