Although the United States has thus far seen very few cases of the coronavirus, its effects continue to disrupt the global market and have implications on the supply chain in the U.S. While these effects have so far been minimal, there remains a fair potential for them to manifest into something greater in the coming months. Shippers, warehouse managers, carriers and other supply chain entities should remain vigilant and adequately prepare their supply chain in the event these disruptions take hold in the U.S.

Important note: as of today, King is reporting no known changes or delays in service by any of its carriers as a result of the coronavirus. We are also not aware of any cases of COVID-19 affecting our personnel or our ability to perform services.

Here’s what you need to know about how the coronavirus is impacting the supply chain and what you can do to prepare for it.

The impact of the halting of production in China

Arguably the greatest impact the disease has had on the supply chain results from the closure of factories in China, where 21% of the value of all goods are imported. These factory closures have impacted many industries by slowing the flow of imported goods to the U.S. The American Association of Port Authorities (AAPA) has stated that cargo volumes at U.S. ports in the first quarter could be down by up to 20% or more from 2019 levels because of the supply chain disruption caused by the coronavirus. While these numbers will rebound eventually, they have significantly slowed the flow of goods through ports.

Capacity could shrink in the coming months

Factories that have been shut down or have had minimal production over the past several weeks are likely to come back online in the coming weeks, and those that have had limited production runs will also eventually ramp up production. When you combine this with the fact that terminal operators in Los Angeles-Long Beach are canceling work shifts due to plunging cargo volumes, which is causing a backlog of empty containers in Southern California and could trigger chassis shortages, this surge of products poses the risk of creating a capacity shortage along with an increase of rates in Q2.

The West Coast is likely to be hit the hardest by shrinking capacity and rising rates in the coming months. As factories come back online and imports surge, an influx of product will be moving through these ports just in time for peak produce season (April – July). Shippers moving freight from these areas should be prepared for these effects to be felt on their supply chains.

What can be done to prepare for shrinking capacity?

As we get closer to the inevitable influx in goods leading to a capacity crunch, there are multiple things shippers can do with their logistics planning to minimize the impact on their business:

- Maintain transparency with supply chain partners: the sharing of information between supply chain entities will be paramount as we seek to prepare for the influx. Shippers should maintain clear and consistent communication with overseas partners, warehouses, carriers and all other supply chain partners. This allows all parties to avoid misinformation and react quickly to changing marketplaces.

- Run possible scenarios: what happens if a shipment becomes stuck at a port? What happens if no carriers are available to haul freight? There are many scenarios that can cause challenges for businesses, and they should be prepared with contingency plans for every possible event.

- Embrace intermodal: long-haul truckers are not the only way to move freight throughout the country. It’s now more important than ever for shippers to embrace intermodal shipping, opening up their options when it comes to moving freight.

- Work with your 3PL: communicate often with your 3PL to discuss your plans and goals for the next few months. Work with them to fine tune your logistics plan to account for the upcoming possibilities.

Contact King with your concerns

Concerned about the impacts of the coronavirus? King is here to answer your questions and help you prepare your supply chain for all contingencies. Contact us today to discuss how our logistics experts can help.

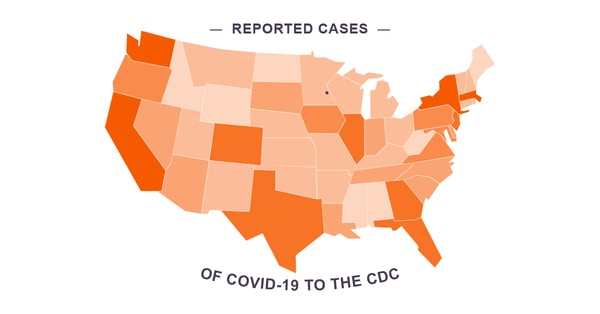

For additional information on COVID-19, please visit the CDC’s website.

Joel Rice

Joel Rice